Jim Nohr helped his family’s business, established in 1978, evolve into NOHR, LLC. in 2018. The business provides quality tooling and rapid prototype casting as well as everything from engineering support to finished parts. They serve several industries including agriculture, forestry, trucking and oil and gas. The company’s ability to provide high quality and complex castings within a quick turnaround time sets them apart from competitors.

Preserving the Family Business

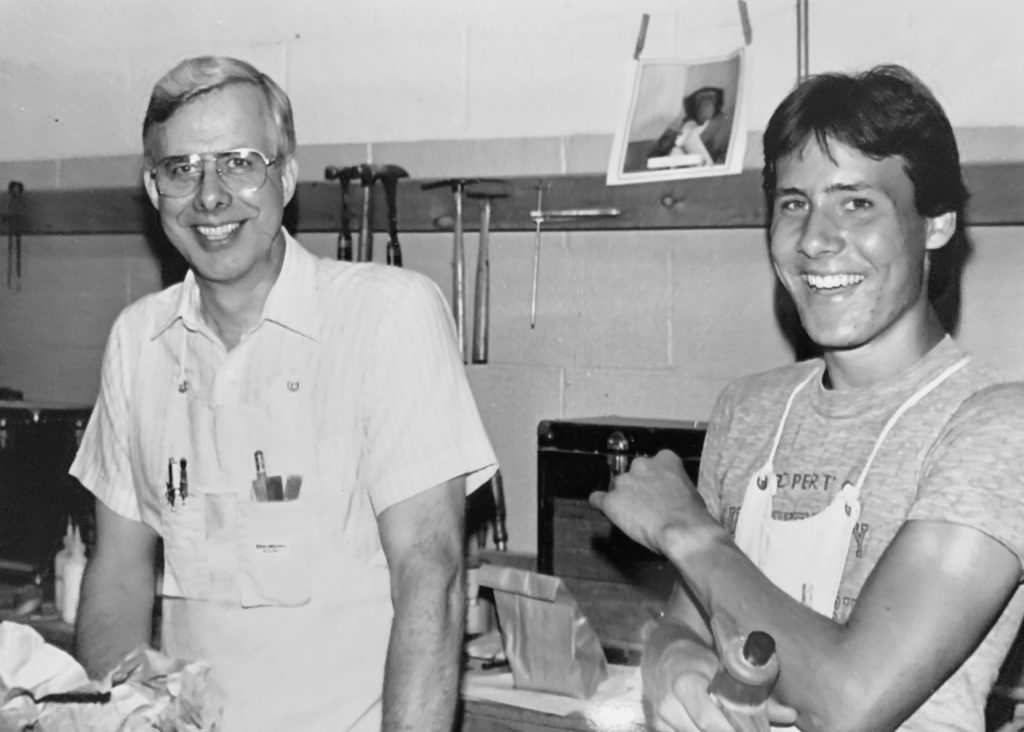

Jim has worked at the business previously titled Nohr Patterns Inc. since he was 18 years old. He came to the UW Whitewater Small Business Development Center (SBDC) in search of guidance for making the transition from old to new, purchasing the existing business owned by his father, Don Nohr. There he met SBDC Consultant Kevin Kaufman. Kevin said of working with Jim, “He has a good, solid business and a great sense of how to run it. He understands sales, operations and finance very well.” Kevin continued, “Jim was thoughtful about seeking advice before making a big decision.”

Overcoming the Obstacles

Lots of challenges presented themselves along the way in the transfer of the family business that included the acquisition of machinery and personnel. To overcome obstacles, Kevin and Jim researched data to determine a fair estimate of the existing business’s worth. Kevin helped Jim determine necessary data to present to Jim’s legal counsel and financial advisors to be sure everyone in the family would be getting a fair deal. Jim was pleased with the interaction, saying, “Kevin’s valuable experience and his belief in my plan helped me overcome my self-doubt.” One of the biggest challenges Jim met was trying to move into a new space by the end of December following the Labor Day purchase. The four-month timeframe required electrical and construction workers to work exclusively on the Nohr project.

Since Jim has taken over ownership, the company has seen many changes. There is now a dedicated shipping and receiving area as well as an inspection room in the 15,000-square foot manufacturing space. He also added new machinery to increase the ability to cut larger patterns efficiently. But perhaps the biggest change is the 50% increase in sales since 2018. Jim attributes the growth not to marketing, but to “satisfied customers and word of mouth.”

Accomplishments with the UW Whitewater SBDC:

- Succession plan

- Data research

- Financial projections

Looking to the Future

This preservation of an existing business has already impacted the local economy by retaining six jobs and adding three new jobs. Kevin and Jim are in the process of searching for a new facility for further expansion as well. Jim said, “Kevin is so easy to get along with. It is like sitting down with an old friend. When I have questions, Kevin replies quickly. His expansive network of connections is always able to help provide answers.”

Jim is currently working to add in-house machining to better control delivery schedules. He wants to continue to grow the business, not only in offerings but also in number of employees. Most importantly, he plans to remain true to the company’s guiding principles of “quality, service and delivery.”